careers

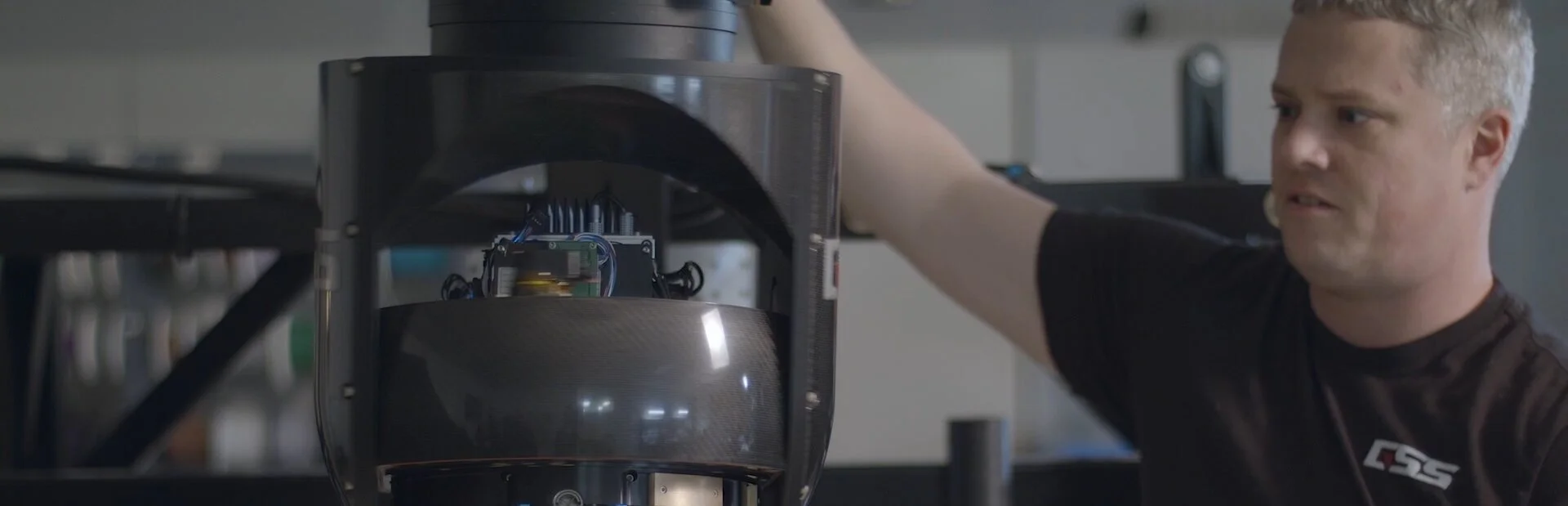

As the industry leader in stabilization technology, GSS offers an inspiring and purpose-driven workplace with the opportunity to create leading-edge technology platforms utilized worldwide.

-

The Role

Design and implement complex, real-time, embedded software systems controlling and supporting inertial stabilization and navigation products. Requires engagement and involvement throughout all phases of the software development life cycle as part of a small, nimble team.

The ideal candidate will have the following:

• Passion for solving problems and providing workable solutions

• A proven track record as a general practitioner of software engineering who can rapidly assimilate and apply new information to existing and emerging problem spaces outside of their direct experience.

• Strong analytical and reasoning skills with an ability to visualize processes and outcomes.

• Proficiency in debugging firmware in tightly coupled hardware systems.

• Ability to support and troubleshoot across a large existing codebase.

• Strong self-management and organizational skills.

• Outstanding all-round communication skills and ability to work collaboratively.

Required Qualifications

• 5+ years of application development experience on Linux, ideally Linux running on resource-constrained platforms in headless appliance-like applications.

• Very strong C and C++ skills including stdlib and POSIX system library familiarity.

• Experience working with embedded ARM microcontroller systems using C and GNU tools.

Highly Desirable Qualifications

• Experience with Yocto-based projects.

• Electronics knowledge and board-level debugging skills.

• Bachelor’s degree in Computer Science, Computer Engineering, Electrical Engineering, or equivalent degree or experience.

• Practical inertial systems experience for pointing, stabilizing, or navigating.

• Experience with motion control techniques and algorithms

EOE

Gyro-Stabilized Systems is an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, national origin, sex, sexual orientation, gender identity, veteran status, and disability, or other legally protected status. If you are unable to submit an application because of incompatible assistive technology or a disability, please contact us at info@gyross.com.

We will make every effort to respond to your request for disability assistance as soon as possible.

-

The primary responsibility of the Electro-Mechanical Assembler shall be to assist in the design, development, manufacturing, and support of gyro-stabilized products (cameras or otherwise) for Gyro-Stabilized Systems.

RESPONSIBILITIES:

* Assemble, rework, and where applicable, test electrical, and mechanical tools and equipment released for manufacturing

* Inspect assemblies, and electronics for workmanship defects

* Support and maintain controls of manufacturing documentation and procedures

* Review diagrams, drawings, and engineering specifications prior to assembly

* Support the engineering change request and product modification processes

* Support the manufacturing information system

* Support the technical training of manufacturing and engineering staff

* Recommend the selection of manufacturing assembly and test equipment

QUALIFICATIONS:

* Ability to understand and assemble complex mechanical systems

* Ability to effectively solder and use crimping tools

* Ability to understand wiring diagrams, system and PCB layouts, and where applicable, test procedures for products and equipment

* Experience with rework, quality requirements, procedures, and standards

* Experience with machining, specifically with a manual mill

* Must have High School Diploma

* Preferred 2-year Technical Certification/Diploma

* Minimum 2 years' experience in an electro-mechanical manufacturing environment

* Must have valid driver's license with acceptable driving record

-

Responsibilities:

Perform all required set-ups on CNC machine centers and/or lathes

Operate CNC and manual machines to produce high-quality parts while maintaining optimal production levels

Monitor machines during operation to ensure proper functionality and prevent malfunctions

Use precision measuring instruments such as dial calipers, snap gauges, and micrometers to verify part accuracy

Identify the appropriate set-up and tooling required for machining specific parts or assemblies

Fabricate component parts to meet engineering and blueprint specifications

Continuously observe machining processes to ensure adherence to quality standards

Set up and operate auxiliary equipment as needed to support machining operations

Machine metal components to desired specifications using both CNC and manual techniques

Qualifications:

Minimum 2 years of experience operating and maintaining CNC equipment; programming skills and technical certifications are a plus

Proven ability to work collaboratively and communicate effectively in a professional and constructive manner

Over 2 years of experience setting up and operating manual machines, including lathes, mills, saws, and drills

Strong knowledge of tooling, feeds and speeds, and Geometric Dimensioning and Tolerancing (GD&T) for various metals and alloys

Extensive experience using precision measuring instruments such as micrometers, calipers, Coordinate Measuring Machines (CMM), and others

Proficient in reading and interpreting blueprints and technical drawings

Proficient with Fusion 360, and knowledge of Haas controls are a plus

Salary range: $45,000 - $71,000 DOE

Please send resume and letter of interest to: finance@gyross.com

Apply here!

To apply, send a copy of your resume and cover letter to info@gyross.com. Please put the job you are applying for as the subject line.